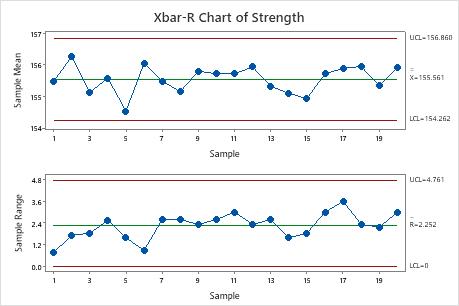

X-Bar and R-Charts can also be used for standardization, which is why data should be collected and analyzed throughout the process operation.

This lets a business determine how a process is running and compare it to historical performance to see if process changes produced the right improvement. X-Bar and R-Charts can be applied to analyze process improvement results.Data must be collected and entered in a manner that enables you to stratify by symptom, operator, location, or time. Different results may be found between shifts among different workers, or different machines and equipment, or among different materials, for example. Once the stability has been assessed, you must figure out if the data needs to be stratified.These subgroups can then be used to measure system stability. First, they would want to collect as many subgroups as possible to accurately calculate control limits.

#Xbar in stats how to#

They may want to figure out how to improve their processes and operations by analyzing results through this statistical method. Take a manufacturing plant, for instance. When improving a system, X-Bar and R-Charts have numerous applications that enable system stability to be evaluated. Applications of X-Bar and R-Chart for System Stability

0 kommentar(er)

0 kommentar(er)